Fully Automatic Bottom Sealing Bag Making Machine for Milk Bag 380MM Bag Length

Technical parameters of our production line:

ZT9804S Tuber machine with servo system

|

Type

|

ZT9804S

|

|

Printing colors

|

4

|

|

Speed

|

80-120BAGS/MIN

|

|

Tube Width

|

380~620mm

|

|

Tube length

|

400-1400mm

|

|

Specification gear

|

51~80 teeth(M=4)

|

|

Type of cutting

|

Step cut&Flat cut

|

|

Number of ply

|

2~4paper+ 1 PP/PE

|

|

Diameter of print roller

|

Ø196~ø312 mm

|

|

Printing width

|

1300 mm(MAX)

|

|

Paper reel diameter

|

Max. 1, 300 mm

|

|

Paper reel width

|

660--1260mm

|

|

Main drive motor

|

47KW

|

|

Servo system

|

YES

|

|

Machine size

|

35.3﹡2.4﹡2.7(M)

|

|

Machine weight

|

N 32(T)

|

HD4916BD Bottomer Machine Performance

|

Speed

|

MAX 80 bags/min

|

|

Tube Width

|

380~620 mm

|

|

Bottom Width

|

80~160 mm

|

|

Valve Sheet Length *Width

|

(100-300)﹡(120-340)adjustable

|

|

Bag Length

|

390~1020 mm

|

|

Bottom Center Distance

|

290~860 mm

|

|

Number of ply

|

2~4paper+1 PP/PE

|

|

Strength sheet unit

|

YES

|

|

Strength sheet length *width

|

(270~520)﹡(80~160)

|

|

Main Drive Motor

|

35KW

|

|

Machine size

|

23.5﹡2.3﹡1.8(M)

|

|

Machine weight

|

N34(T)

|

Features of our full-automatic paper bag production line:

1. High Speed Rotary Feeder

2. Tube Alignment

3. Deflector for Irregular Tubes

4. Bottom Creasing Line Station

5. Air Vent Perforation

6. Bottom Opening Unit

7. Valve Station with Winding Station

8. Pasting Internal Strengthen Sheet Unit

9. Bottom Closing Stations

10. Pasting External Strengthen Sheet Unit

Our machine:

Automatic valve paper bag machine for cement,chemicals and food

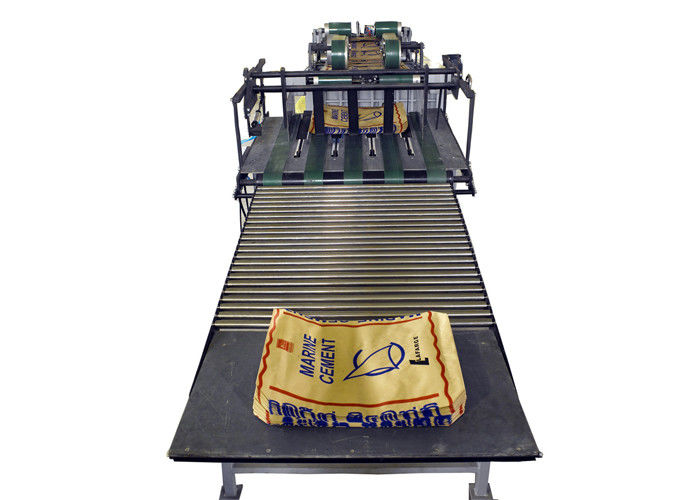

Sample bags:

Applications:

The ZT9804S tuber machine,which is developed by our company on the basis of ZT9804 standard

tuber machine, is added a servo control component on each of the four key procsses (printing,

perforation, gluing and separation), to form a closed loop servo control system by the PLC, servo

control module, the main frequency traction motor, servo motor group,encoder, color components

to ensure that the cutting position of each printing bags matches the color patch of the tube.

Through the touch screen, it is easy and visualized to adjust the specification of tube.When it is on-line

printing, ZT01 print unit prints precisely and neatly, and it only needs to replace print roller and

its gear. Through adjustment of thorn ranked knife position, ZT07 separation machine can cut both

the ladder cutting and straight cutting tubes. Other related adjustments are operated on touch screen,

saving of labor and time .

When it is not on-line printing, besides the above characteristics, when requires more high precision

printing quality,

it can complete printing by the using of other printing equipments, producing tubes in ZT9804S

Tuber machine, expanding the specification of tubes of ZT9804S(400mm to 1400mm). Need not to

change any specification wheel, all adjustments are operated on the touch screen.

ZT9804S is applicable to producing variety of paper bags, especially when in producing starch paper

bags, tea bags, chemical bags and so on, which need frequent specification changing and high-precision

printing quality, it can fully play its unique advantages.

Welcom to contact us or visit our .we are ready here.