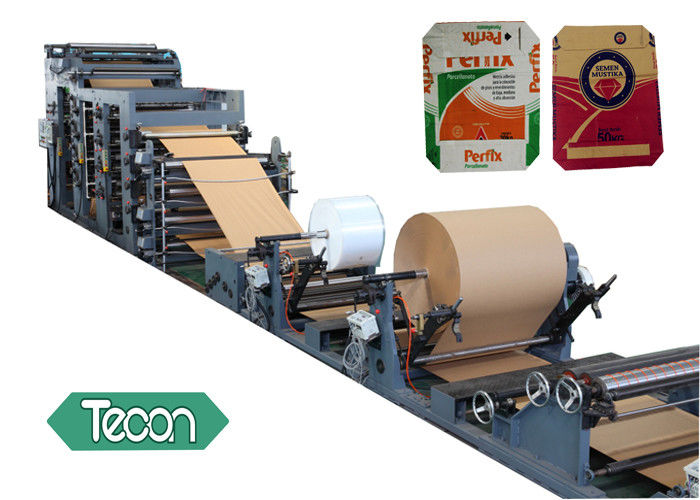

Cement Bags Production Line Paper Tube Making Machine with PP Film Laminated

Specifications:

It is used for producing valve cement paper bags with printing. The main motor adopts frequency conversion motor to save more electricity and regulate speed more freely. The color code tracker with good performance makes the sealing and cutting length more accurate and the error smaller. It adopts advanced computer to adjust length more freely and accurately.It can make one printed bag and three unprinted bags one time, or four unprinted bags one time in allowed width.

Basic model: ZT9804&HD4913

Machine technical parameter:

| Tuber Speed: |

130~150 tubes/min |

| Bottomer speed: |

80~130 bags/min |

| Diameter of print roller: |

ø144~ø314 mm |

| Printing width: |

1300 mm(MAX) |

| Paper reel width: |

860~1260 mm |

| Paper reel diameter: |

Max. 1, 300 mm |

| Size of tuber: |

34.3m*2.4m*2.7m( L*W*H) |

| Size of bottomer: |

22m*1.8m*1.8m ( L*W*H) |

| Air consumption: |

1,100L/min |

| Power consumption: |

63kw(ZT9804 30KW,HD4913 33KW) |

Paper Bag details:

| Bag Width: |

420~600 mm |

| Bottom width: |

90~130mm |

| Length: |

520~880mm,longer can be customized. |

| Number of plies: |

2~4 papers and 1 PP/PE liner obtional. |

| Colour printing: |

4 colors available (ZT9802 is 2 color printing) |

Base paper Bleached or unbleached paper is available, with grammages ranging from 70g sm to 120 gsm. Polycoated plies or HDPE films can be incorporated if required for enhanced moisture protection.

Service

(1) Pre-sale service

We are so glad to welcome the customer to visit our factory and show our machine’s working. And we will take you to our domestic customers’ factory who have bought our machine for watching the machine daily operation. We will haveing meetings with the customers for discussion on the machine, price, service or any part concerns. At the same time, we make meeting records and finally close the deal.

(2) Medium-sales service

1. After signing the contract, we will provide the production planning to the customer. In addition to this, we will follow up the production progress and report to the customer production situation regularly.

2. The part of Inspection. When the machine production finished, we will invite the buyer coming to our factory for watching the machine operation. For example, the buyers have a requestment for producing 1 or 2 various sizes paper bags. We will show the machine making paper bags the same as samples provided by buyers. We will arrange the shipment if the customers satisfied with the machine.

3. Transportation. Wooden boxes packaging in container, the whole set of machine needs 5x40GP. About the freight forwarder, we can find for you or use your recommended. We will provide a few good service freight forwarders to let you choose.

(3).After sales service

We will arrange the engineers to the buyer’s factory for installation, commissioning and training.

a. The seller shall dispatch 4 qualified engineers to the job site for the erection, commissioning, and training. The buyer shall make available of testing facilities and skilled personnel as well as utilities and all raw materials in the specified quantity and quality.

b. The buyer should accept the equipment after it reaches the technical performance indicated.

c. We will give some wearing parts to buyer for free. The warranty of machine is one year.

Industrial bags

Bottomer bottom open unit